3-D Printers

Comments

-

-

-

#3dprintshowI miss igotid880

-

-

-

i got scanned at comic-con in NY. But they never sent me the emailI miss igotid880

-

8/28/98- Camden, NJ

10/31/09- Philly

5/21/10- NYC

9/2/12- Philly, PA

7/19/13- Wrigley

10/19/13- Brooklyn, NY

10/21/13- Philly, PA

10/22/13- Philly, PA

10/27/13- Baltimore, MD

4/28/16- Philly, PA

4/29/16- Philly, PA

5/1/16- NYC

5/2/16- NYC

9/2/18- Boston, MA

9/4/18- Boston, MA

9/14/22- Camden, NJ

9/7/24- Philly, PA

9/9/24- Philly, PATres Mts.- 3/23/11- Philly. PA

Eddie Vedder- 6/25/11- Philly, PA

RNDM- 3/9/16- Philly, PA0 -

I miss igotid880

I miss igotid880 -

-

Looking forward to that!0

-

Serious question... do you think when 3D printing becomes more mainstream & affordable that it will be the death of Lego as a company?Star Lake 00 / Pittsburgh 03 / State College 03 / Bristow 03 / Cleveland 06 / Camden II 06 / DC 08 / Pittsburgh 13 / Baltimore 13 / Charlottesville 13 / Cincinnati 14 / St. Paul 14 / Hampton 16 / Wrigley I 16 / Wrigley II 16 / Baltimore 20 / Camden 22 / Baltimore 24 / Raleigh I 25 / Raleigh II 25 / Pittsburgh I 250

-

Unless Lego (and many other companies) adapts to this manufacturing revolution...Then sure, they can go outta business.HesCalledDyer said:Serious question... do you think when 3D printing becomes more mainstream & affordable that it will be the death of Lego as a company?

Just print your own Lego, print your own toys, print your own gun.

Real wealth (in this case) is knowing about CAD files, knowing how to design things, to make/print them.

Having said that, I'm not sure what intellectual property rights Lego has etc.

Also, its gonna take maybe 5-10 years for us (at home) to print a piece (of lego) as good as Lego themselves make them.

I've tried, its not easy, the end results now are not up to actual Lego standards (yet).

Many companies should be worried...in 10-15 years, 3D printing will be everywhere.

0 -

yea there's a place that makes dentures and I'm wondering what will happen to them in a few years.Idris said:

Unless Lego (and many other companies) adapts to this manufacturing revolution...Then sure, they can go outta business.HesCalledDyer said:Serious question... do you think when 3D printing becomes more mainstream & affordable that it will be the death of Lego as a company?

Just print your own Lego, print your own toys, print your own gun.

Real wealth (in this case) is knowing about CAD files, knowing how to design things, to make/print them.

Having said that, I'm not sure what intellectual property rights Lego has etc.

Also, its gonna take maybe 5-10 years for us (at home) to print a piece (of lego) as good as Lego themselves make them.

I've tried, its not easy, the end results now are not up to actual Lego standards (yet).

Many companies should be worried...in 10-15 years, 3D printing will be everywhere.I miss igotid880 -

I'm just reading William Gibson's new novel The Peripheral, set in some undefined but slightly futuristic time when 3D printing appears to be the norm and you go to chain stores like "Fabbit" to have your goods made. A glimpse at what the world might be like if this is the reality; and yes, they do fab weapons. (a great read, by the way, for any interested)my small self... like a book amongst the many on a shelf0

-

Sounds interesting.oftenreading said:I'm just reading William Gibson's new novel The Peripheral, set in some undefined but slightly futuristic time when 3D printing appears to be the norm and you go to chain stores like "Fabbit" to have your goods made. A glimpse at what the world might be like if this is the reality; and yes, they do fab weapons. (a great read, by the way, for any interested)

UPS,FedEx etc started experimenting with 3D printing in some locations, Staples too.

I've been working on Setting shop up, starting a school for 3D printing (for kids).0 -

These things blow my mind.

I am really enjoying watching things that are literally from the imagination of Gene Roddenberry become reality. Anyone else who is an ST: TNG nerd loving how modern technological advancement often stems from Star Trek ideas?? Like, for real? I think that's so cool!! :-BWith all its sham, drudgery, and broken dreams, it is still a beautiful world. Be careful. Strive to be happy. ~ Desiderata0 -

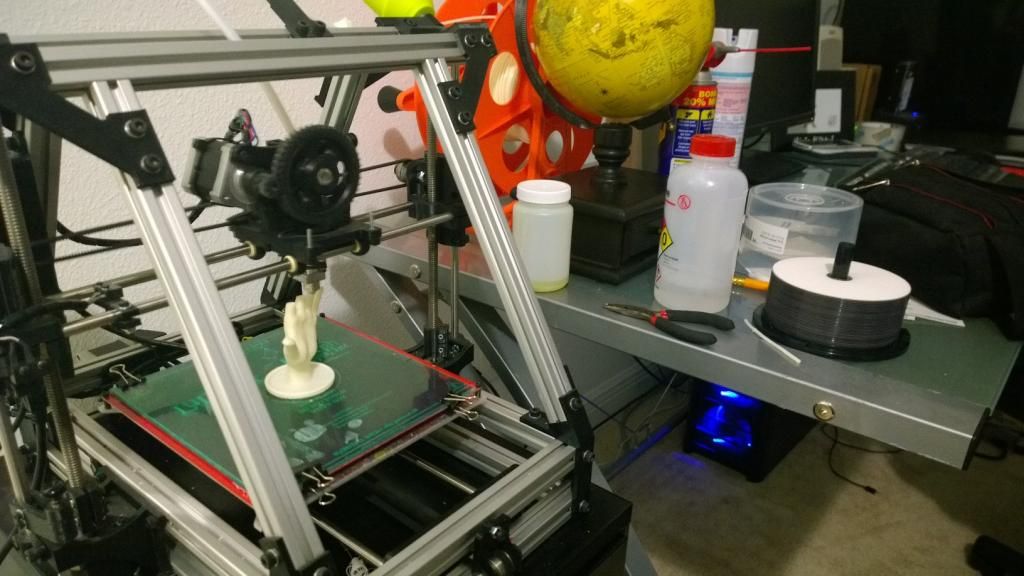

This is an old pic of the first machine we printed with (In our work shop), we run a few printers now.

Our PC Lab,

0 -

I miss igotid880

I miss igotid880

Categories

- All Categories

- 149.1K Pearl Jam's Music and Activism

- 110.2K The Porch

- 283 Vitalogy

- 35.1K Given To Fly (live)

- 3.5K Words and Music...Communication

- 39.4K Flea Market

- 39.4K Lost Dogs

- 58.7K Not Pearl Jam's Music

- 10.6K Musicians and Gearheads

- 29.1K Other Music

- 17.8K Poetry, Prose, Music & Art

- 1.1K The Art Wall

- 56.8K Non-Pearl Jam Discussion

- 22.2K A Moving Train

- 31.7K All Encompassing Trip

- 2.9K Technical Stuff and Help

https://www.youtube.com/watch?v=CdXlrk0b3rA

https://www.youtube.com/watch?v=CdXlrk0b3rA